Some of you will not understand the pain and sadness of putting a crack in a £300 ukulele… And I hope you never will…

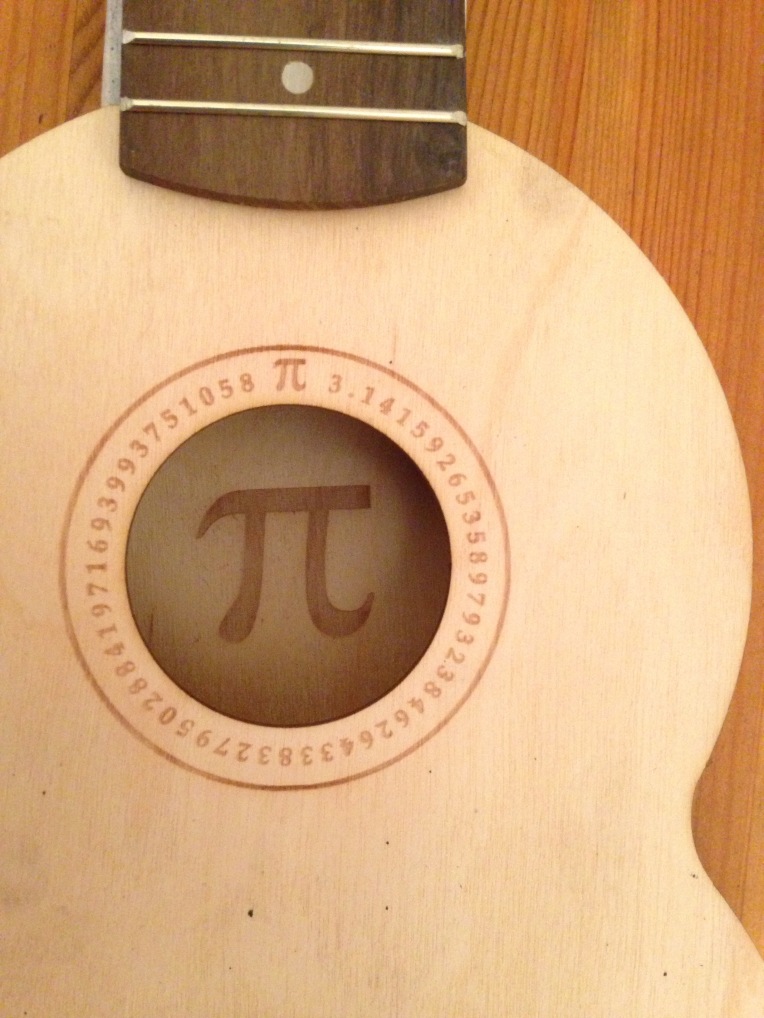

Irrational…

Have you seen my lunchbox?

So, the tupperware box ukulele has been finished!

Sounds decent enough, here’s the video:

And yes, some lost their lunch box.

Whoa, Bendy

Attached the neck, but boy is that box bendy :S

We’re going to have to see if the string tension is going to do anything to it, other than add vibrato all the time.

Lunch box

After reading Got A Ukulele’s rather… blunt review on the Alic Ukulele, I thought ‘why not?’

So, before I get into my project, I have to say the Alic Ukulele is probably, hands down, my favourite ukulele. I’ve had it for little under a week and it is just brilliant. Please check it out. I, for one, am impressed with the Alic, and likewise the Flea. It’s just that the Alic right now, is a much better investment for me.

Anyway, it is the sound of the Alic which made me fall head over heels, and in Got A Ukulele’s review, one line stood out. It was “but really… Wooden neck attached to plastic lunchbox”

And I thought, what sound would come from a wooden neck attached to a plastic lunch box? If it’s like the Alic, or the Flea that that takes after, then maybe we’ll be seeing more plastic backed ukes.

No lunch box, but I had a 1.4L tubberware box, so let’s see how this turns out. 😀 And here I thought my ukulele making days were numbered.

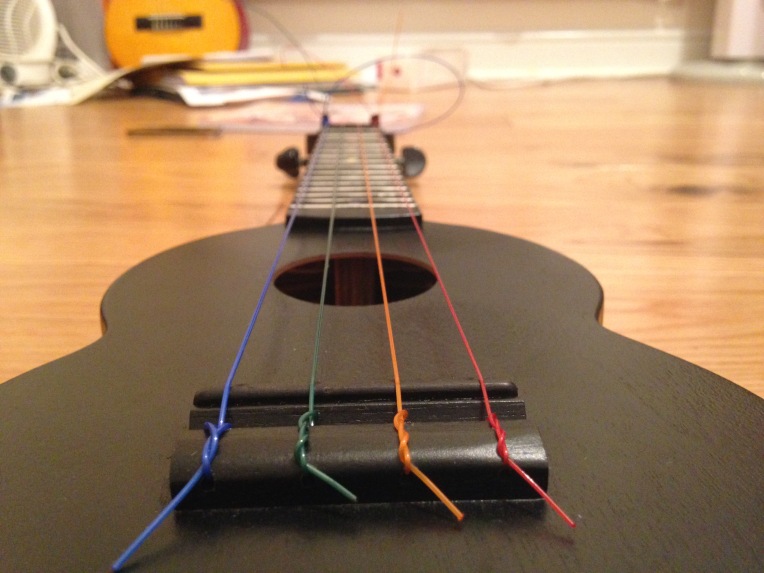

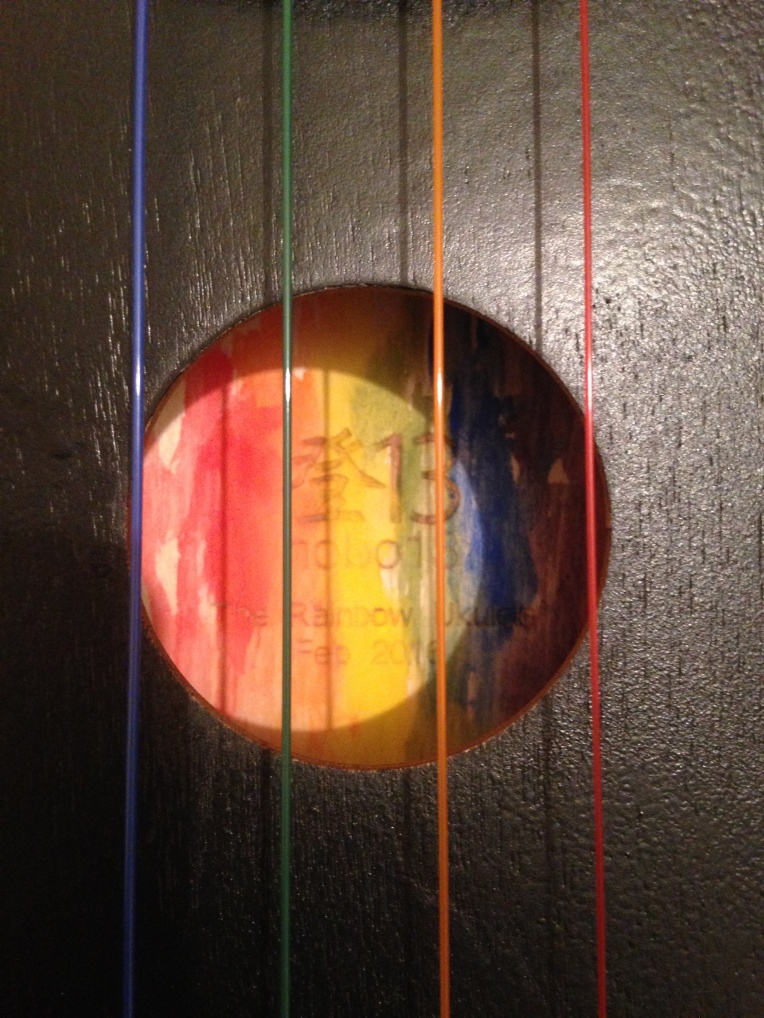

The Rainbow Ukulele

Presenting the rainbow ukulele, the one I should really have named the refraction ukulele. Featuring the colourful strings by Aurora (which is an Aquila product.)

The strings are a beautiful addition, but they are a high g standard set. I’ve strung it in order of thickness to achieve a low g tuning, making adjustments to the nut to accommodate this. There isn’t a lot of tension in that low g however, it isn’t ringing like the rest.

Rainbow fret markers are always a pleasure to do 😀

Added a little paint inside as well.

Something dark

The Hurt Ukulele

So, here is the Hurt Ukulele.

It is bare, as in no finish has been done to the uke. I made this with the sole purpose of testing how much damage it could take, so here it is:

The little thing took a lot of damage before some buzzing happened. I am fairly certain this was caused by something only in this uke, so I am confident my ukes will take a beating. Tuners aside, the only damage I see is some minor dents from when I was hitting it with a sword.

Video aside, here is the usual build process for my laser cut ukes.

Half term projects: Old and New

Half term is here, and I have time to play around again. I have had these tonewoods for a while now, begging to be made into an uke. Unfortunately, they’ll have to wait a little longer as I need to buy a bending iron. That’s an expensive tool that I should probably have to justify, seeing as this is a hobby. Bah, I’m going to buy it anyway.

At the same time, I’m still continuing with the laser cut ukes I’ve been making. This one will probably not see much action as I am going to break it. For science. I wanted to know how much force these things could withstand after a friend said their’s broke. I have a gut feeling it was because of the direction of the grain as it was a solid wood, so it shouldn’t affect my laser cut ones, but I am still curious. I’m a little attached to all my ukes (total understatement) so it’ll be sad when it does fufill its duty…

And yes, my desk top is dirty. Heck, there’s even a bloody tissue there! What can I say? I bleed a lot apparently.